Plastic injection molding is a cornerstone of modern manufacturing, offering efficiency, precision, and scalability for producing a wide range of plastic products. From automotive parts to household items, plastic injection molds are used in almost every sector, making them one of the essential tools in industrial production. This process involves injecting molten plastic into a mold cavity under high pressure, allowing the material to cool and solidify into a final product. The primary benefit of plastic injection molding is its ability to create highly intricate designs with tight tolerances, which is crucial for industries where precision and durability are key.

Plastic injection molds are vital to the manufacturing process because they allow for the mass production of plastic components with consistent quality and uniformity. One of the key advantages is that they can be used to produce complex shapes that would otherwise be difficult, if not impossible, to create using other manufacturing methods. This ability to mold intricate features efficiently and accurately reduces the need for additional assembly work or post-production processes.

Plastic injection molding provides material consistency and repeatability, ensuring that each produced part is almost identical to the next. This is essential for industries that require large volumes of products made to exact specifications. The process is also highly adaptable to different types of plastics, which can be tailored for specific applications, such as high-temperature resistance or flexibility. With the precision of injection molding, manufacturers can meet the stringent demands of various industries, from electronics to automotive, medical devices, and beyond.

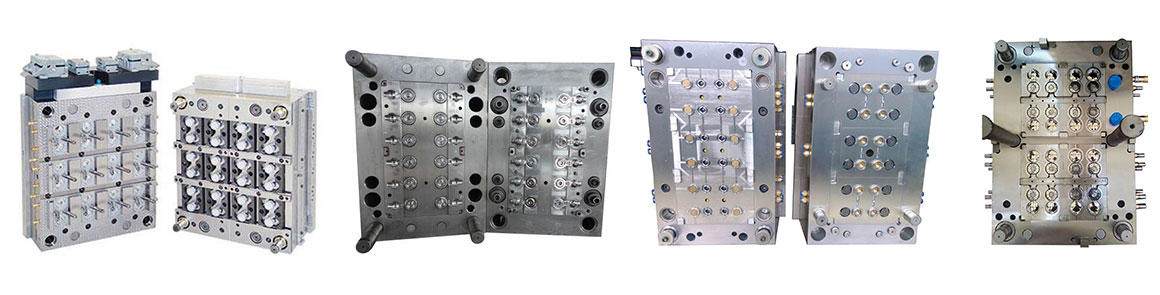

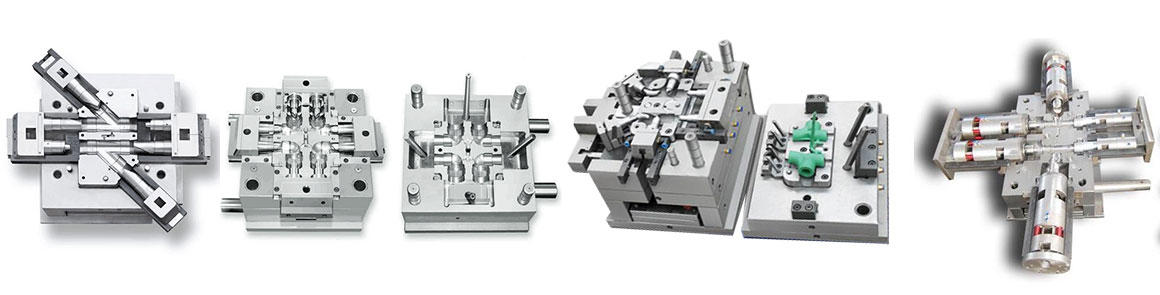

Custom injection molds provide manufacturers with a tailored solution that optimizes the production process for specific needs. Unlike off-the-shelf molds, which are designed for general use, custom molds are created to fit the unique requirements of a particular product or product line. This customization allows for the design of molds that maximize efficiency, minimize waste, and ensure better overall performance in production.

One of the primary advantages of custom molds is that they are designed with the specific geometry and material requirements of a product in mind. This allows for enhanced design flexibility, meaning manufacturers can produce complex shapes or features that are not possible with standard molds. Additionally, custom molds allow for better control over part quality, ensuring that every piece meets the desired specifications.

Another significant benefit is cost-efficiency in the long term. While the initial investment in custom molds can be higher compared to standard molds, the precision and efficiency they provide in the production process often bring about significant cost savings over time. Custom molds reduce the likelihood of defects or waste, and they can help streamline the production process, reducing labor and material costs.

In industries where high-volume production and precision are essential, custom molds ensure that the process is not only efficient but also sustainable. They offer manufacturers the opportunity to stay competitive in a rapidly evolving market by providing consistent and high-quality products.

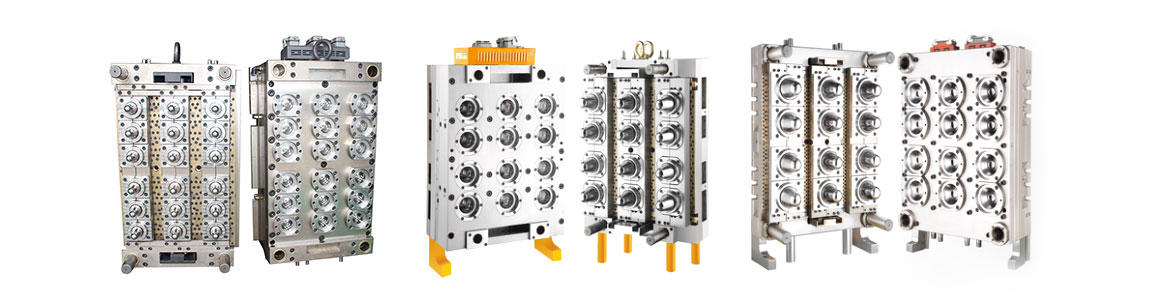

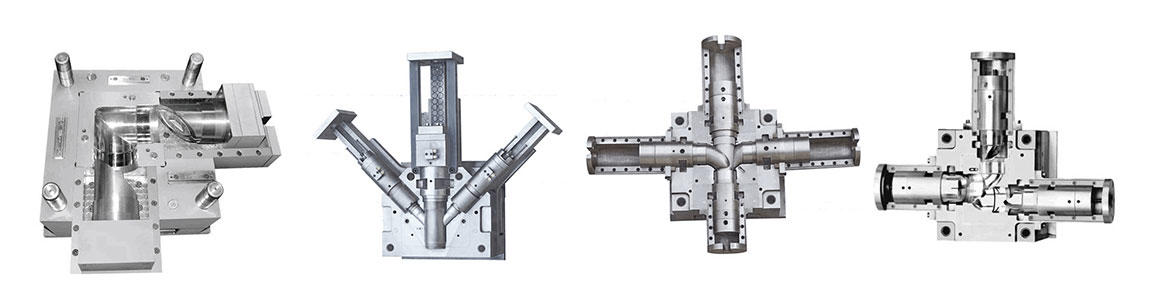

Multi cavity injection molds are an advanced solution that increases production efficiency by enabling the simultaneous production of multiple parts in a single injection cycle. This type of mold is designed with several cavities, each capable of producing the same or different parts at the same time, which significantly boosts the output of a single molding machine. Multi cavity molds are especially beneficial in high-volume manufacturing, where productivity is a key objective.

One of the significant advantages of multi cavity molds is that they drastically reduce cycle time. Since multiple parts are produced in one shot, the time it takes to produce each unit is greatly reduced, bring about higher throughput and lower overall production costs. This also improves the cost-per-unit efficiency, as the cost of materials and machine time is spread across multiple parts.

Multi cavity molds also contribute to improved consistency and quality. Since each cavity is filled at the same time, the pressure and material distribution are uniform, which results in parts that are more consistent in weight, size, and appearance. This is particularly important in industries that require high levels of precision and uniformity in their products, such as the medical or automotive sectors.

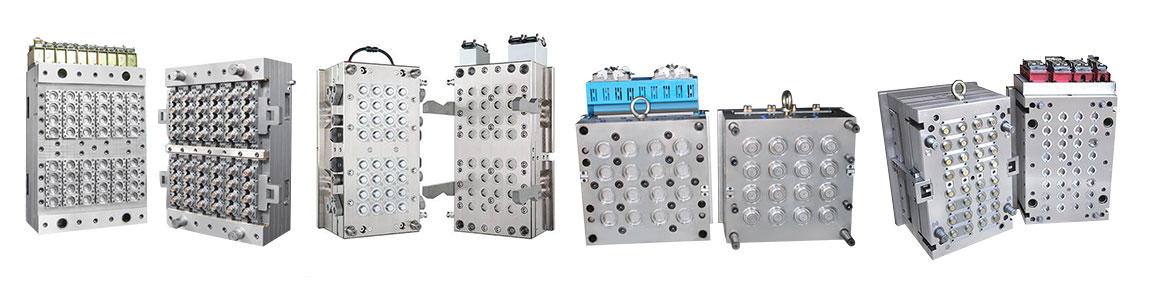

Taizhou Huangyan Yongsheng Mould Co., Ltd. is famous China Plastic Mould Maker and Plastic Mold designer, founded in 2011, is located at Zhejiang province china mould town Huangyan. beautiful surrounding, convenient traffic, superior geography location. close to the nearby Hangzhou and Ningbo port, we are specializing in the development, Needle valve preform molds, various cap molds, automatic flip molds, medical injection molds, packaging molds, pipe fitting molds, bottle blowing molds, household molds, etc. We are adopting the world advanced designing software of CAD/UG/VT/ST, and we have had first-class experts and production machines.

Polyethylene Terephthalate (PET) has been a popular material in the packaging industry for decades due to its clarity, strength, and chemical resistan

Plastic injection moulding is one of the widely used manufacturing processes for producing plastic parts, ranging from small components to large, intr

The medical industry has long required packaging solutions that meet stringent hygiene, safety, and functional standards. With the increasing demand f

Medical syringes are essential instruments in healthcare, used for administering medications, vaccines, and drawing fluids. The production of medical

Automatic Flip Top Cap Mould Manufacturing Exporter Producer One of the important features of the automatic flip top cap mould is its ability to produ

What is Plastic Mould

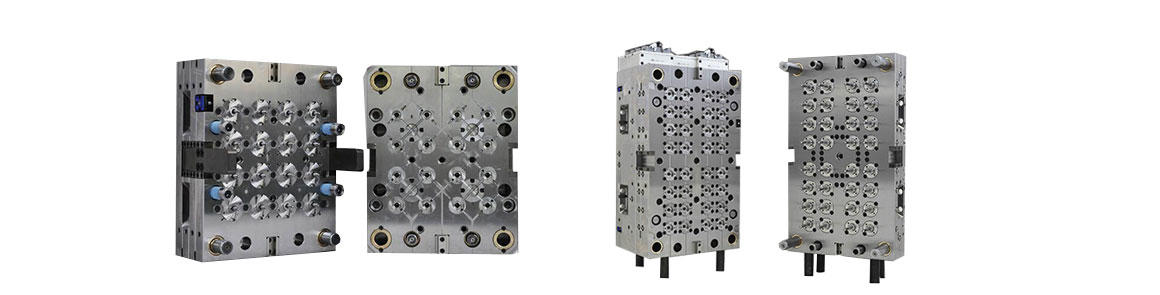

A plastic mold is a tool used to give shape to molten plastic as it cools and solidifies. The mold is typically made of steel or aluminum and consists of two halves that are clamped together during the injection molding process. The inside of the mold is shaped like the desired final product, and the molten plastic is injected into the mold under high pressure. As the plastic cools and solidifies, it takes on the shape of the mold. Once the plastic has hardened, the mold is opened and the finished product is removed. Plastic molds are used in a wide range of industries, including automotive, medical, and consumer goods.