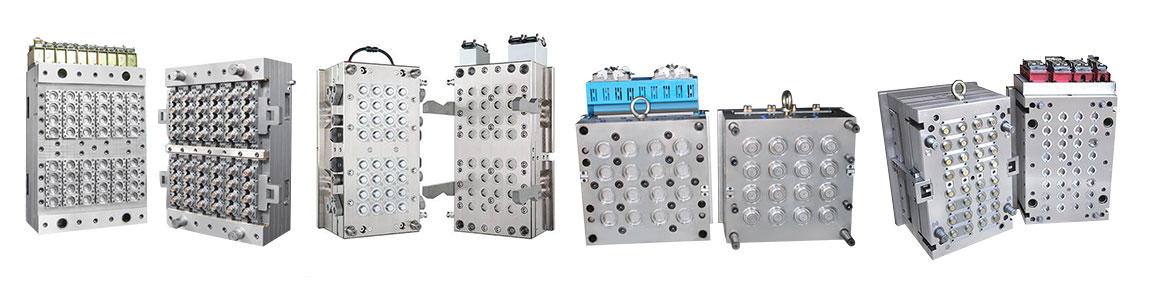

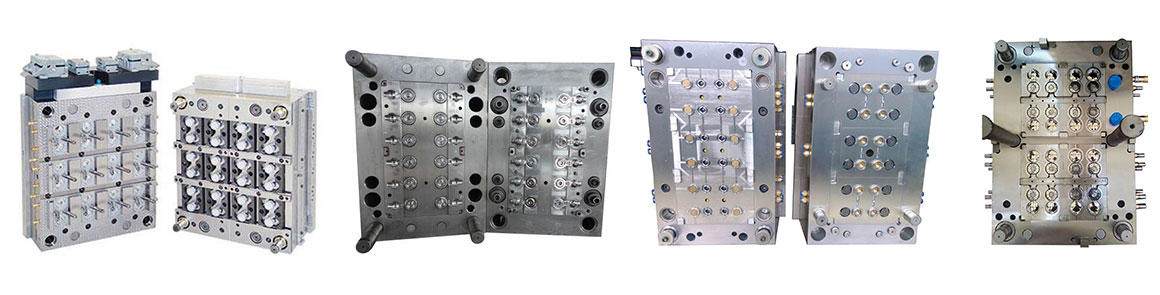

Taizhou Huangyan Yongsheng Mould Co., Ltd. is famous China Flip Cap Mould Manufacturers and Flip Cap Mold factory, founded in 2011, is located at Zhejiang province china mould town Huangyan. beautiful surrounding, convenient traffic, superior geography location. close to the nearby Hangzhou and Ningbo port, we are specializing in the development, Needle valve preform molds, various cap molds, automatic flip molds, medical injection molds, packaging molds, pipe fitting molds, bottle blowing molds, household molds, etc. We are adopting the world advanced designing software of CAD/UG/VT/ST, and we have had first-class experts and production machines.

Sale High Quality OEM Syringe Mould Manufacturers Factory In the fast-paced medical industry, syringe mould manufacturers play a crucial role in suppl

China Sale Custom Syringe Mould Manufacturers Wholesaler Syringe mould manufacturers are at the forefront of a critical industry that supports the hea

High Quality Syringe Mould Manufacturers Company in China Syringe mould manufacturers are integral to the medical and pharmaceutical industries, provi

Wholesale Syringe Mould Manufacturers Producer in China Syringe mould manufacturers play a pivotal role in the healthcare industry, providing essentia

Sale High Quality Plastic Cap Mould Manufacturers in China In the modern era, where environmental consciousness is at an all-time high, plastic cap mo