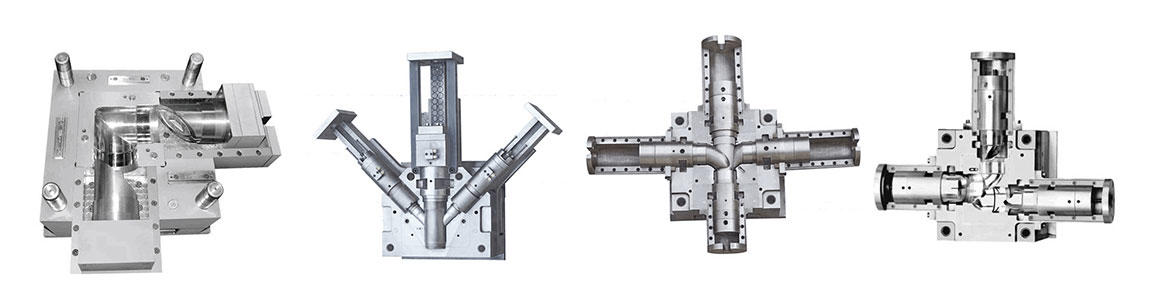

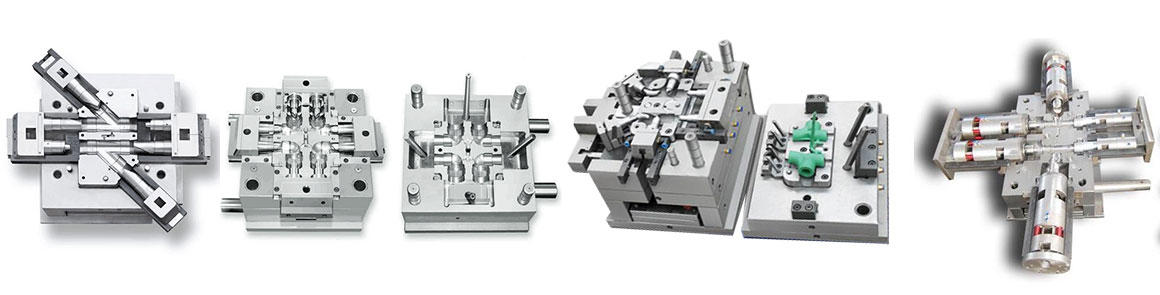

Taizhou Huangyan Yongsheng Mould Co., Ltd. is famous China Plastic Pipe Fitting Mould Manufacturers and Plastic Pipe Fitting Mold factory, founded in 2011, is located at Zhejiang province china mould town Huangyan. beautiful surrounding, convenient traffic, superior geography location. close to the nearby Hangzhou and Ningbo port, we are specializing in the development, Needle valve preform molds, various cap molds, automatic flip molds, medical injection molds, packaging molds, pipe fitting molds, bottle blowing molds, household molds, etc. We are adopting the world advanced designing software of CAD/UG/VT/ST, and we have had first-class experts and production machines.

Polyethylene Terephthalate (PET) has been a popular material in the packaging industry for decades due to its clarity, strength, and chemical resistan

Plastic injection moulding is one of the widely used manufacturing processes for producing plastic parts, ranging from small components to large, intr

The medical industry has long required packaging solutions that meet stringent hygiene, safety, and functional standards. With the increasing demand f

Medical syringes are essential instruments in healthcare, used for administering medications, vaccines, and drawing fluids. The production of medical

Automatic Flip Top Cap Mould Manufacturing Exporter Producer One of the important features of the automatic flip top cap mould is its ability to produ