Medical injection molding plays a critical role in the production of medical devices and components used in healthcare, from simple syringes to complex diagnostic equipment. The process involves creating highly precise and consistent parts through the injection of molten plastic or other materials into molds. These molds are carefully engineered to meet stringent regulatory standards and the specific needs of the medical industry.

Medical molds are used in the production of a wide variety of medical devices, ranging from consumables like syringes and catheters to more intricate components used in diagnostic and surgical tools. The function of these molds goes beyond merely shaping a product; they ensure that medical devices are produced with the precision and safety in mind. For medical products, the integrity and performance of the molded part are crucial for both patient safety and the overall effectiveness of the device.

One of the significant aspects of medical injection molding is the ability to produce parts that meet the standards of hygiene, functionality, and sterility. Medical molds need to allow for the creation of parts that are not only durable but also free from defects that could impact the device's performance or safety. The process enables high-volume production with consistent quality, which is vital in industries where each component's reliability is critical. Medical molds also need to be versatile, allowing manufacturers to create a range of shapes and sizes, depending on the specific application.

The materials used in medical injection molding are crucial to the success and safety of medical devices. The right material can impact the device's durability, safety, and ability to function in a medical environment. Common materials used for medical injection molds include thermoplastics like polyethylene (PE), polypropylene (PP), and polycarbonate (PC). These materials are known for their ability to be molded into complex shapes, their flexibility, and their resistance to chemicals and sterilization processes.

Polypropylene, for example, is frequently used in medical device production due to its chemical resistance and low moisture absorption. It is often employed in creating medical consumables such as syringes, containers, and IV components. Polycarbonate, on the other hand, is chosen for its strength and transparency, making it ideal for parts that need to be both durable and visible, such as medical diagnostic equipment or surgical tools.

Medical injection molds are created by specialized suppliers who provide the expertise and technology required to ensure that each mold meets the high standards of the medical industry. When selecting a supplier, it is essential to consider their experience, technical capabilities, and commitment to quality control. Reputable medical injection mold suppliers understand the unique demands of the healthcare sector, including the need for compliance with regulatory standards such as ISO 13485 and FDA guidelines. These certifications ensure that the supplier's products meet the stringent requirements for safety, performance, and reliability.

A professional supplier will work closely with medical device manufacturers to understand the specific requirements of each product and design a mold that can meet those needs. This collaboration is crucial in ensuring that the molds are produced with the precision necessary for medical devices. Suppliers also offer a range of services beyond mold creation, including design assistance, prototyping, and post-production support.

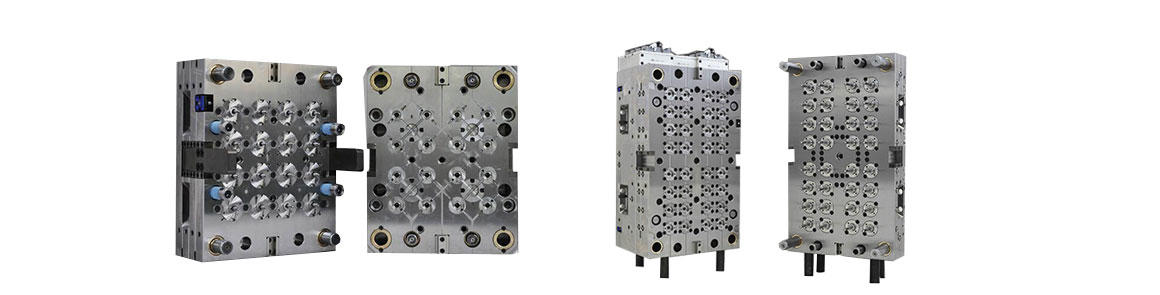

Additionally, suppliers of medical injection molds invest heavily in technologies, including automated systems for mold making, advanced injection molding machines, and quality inspection tools. This ensures that the molds can be produced efficiently while maintaining the levels of accuracy and consistency.

In recent years, the role of medical injection mold suppliers has expanded to include more advanced materials and technologies, allowing them to meet the evolving needs of the medical field. For instance, some suppliers offer rapid prototyping services, which allow manufacturers to test and refine their product designs quickly before committing to full-scale production. This capability is particularly valuable in a fast-paced industry where time-to-market can be crucial.

Taizhou Huangyan Yongsheng Mould Co., Ltd. is famous China Medical Packaging Mould Manufacturers and Medical Packaging Mold factory, founded in 2011, is located at Zhejiang province china mould town Huangyan. beautiful surrounding, convenient traffic, superior geography location. close to the nearby Hangzhou and Ningbo port, we are specializing in the development, Needle valve preform molds, various cap molds, automatic flip molds, medical injection molds, packaging molds, pipe fitting molds, bottle blowing molds, household molds, etc. We are adopting the world advanced designing software of CAD/UG/VT/ST, and we have had first-class experts and production machines.

Polyethylene Terephthalate (PET) has been a popular material in the packaging industry for decades due to its clarity, strength, and chemical resistan

Plastic injection moulding is one of the widely used manufacturing processes for producing plastic parts, ranging from small components to large, intr

The medical industry has long required packaging solutions that meet stringent hygiene, safety, and functional standards. With the increasing demand f

Medical syringes are essential instruments in healthcare, used for administering medications, vaccines, and drawing fluids. The production of medical

Automatic Flip Top Cap Mould Manufacturing Exporter Producer One of the important features of the automatic flip top cap mould is its ability to produ

What is Medical Packaging Mould

Medical packaging mold refers to the mold used to create containers for medical products such as pills, capsules, and vials. These molds are typically made from a variety of materials such as plastic, metal, or glass, and are specifically designed to meet the requirements of the medical industry, including safety, hygiene, and functionality. The molding process used to create medical packaging can include injection molding, blow molding, or other methods, depending on the type of product being packaged.

Advantages of Medical Packaging Mould