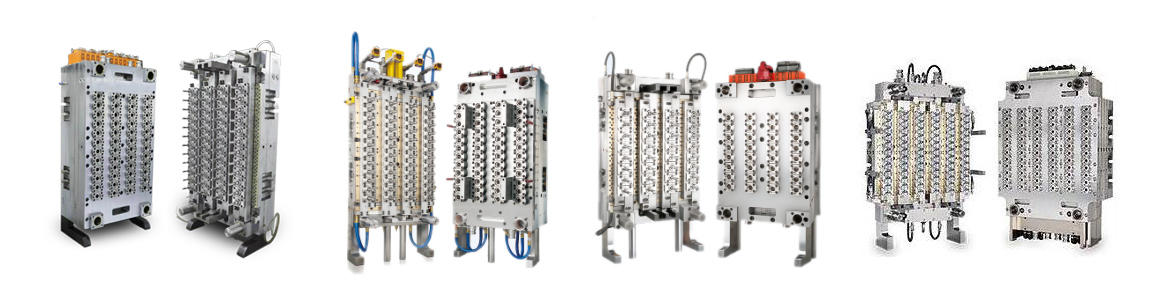

Preform molds are used to create plastic preforms, which are intermediate products that are later expanded and shaped into the final desired form through blow molding. These molds are essential for producing items such as plastic bottles, jars, and other hollow containers.

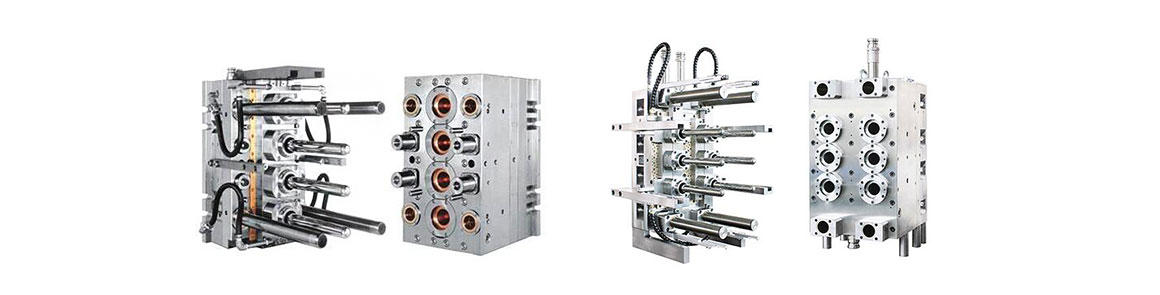

Injection Molds: The common type of preform mold, injection molds are typically used in the production of preforms made from materials like PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), or PP (Polypropylene). These molds work by injecting molten plastic into a pre-designed cavity to form the preform shape. They are well-suited for high-precision products and mass production, as they can produce large quantities quickly and consistently.

Hot Runner Molds: A variant of injection molds, hot runner molds have a system that keeps the plastic material at the temperature to reduce waste and improve cycle times. These molds are commonly used for producing high-quality preforms, as they minimize the risk of material degradation.

Cold Runner Molds: These molds are a bit more traditional and are often used in situations where precise control over the molding process is required. Cold runner molds involve channels through which molten plastic is injected into the mold. The key difference here is that the material in the runners can cool down, which can bring about some waste but allows for a different kind of mold design flexibility.

The preform mold selection largely depends on the material to be used and the specific needs of the production process, such as cycle time, precision, and cost.

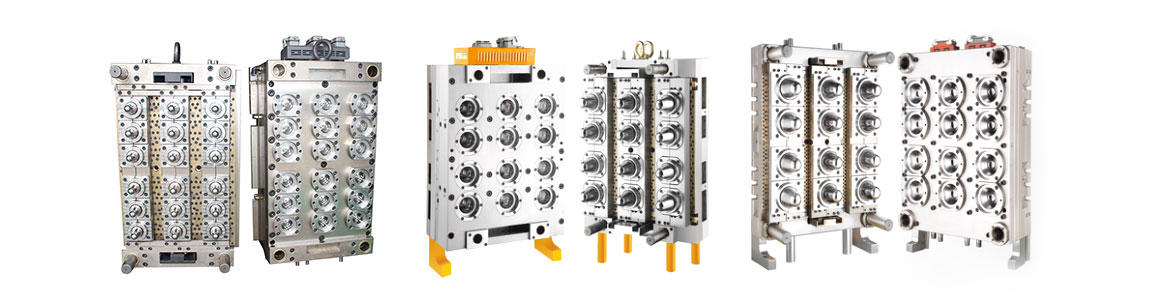

PET preform molds are specialized injection molds used to produce preforms made from PET plastic. These preforms serve as the initial shape from which plastic bottles or containers are formed through blow molding.

Precision and Consistency: PET preform molds are known for their high precision. The molds must be able to create preforms with uniform wall thickness, ensuring the finished product is durable and can handle pressure during the blow molding process. The molds must maintain tight tolerances, as even a minor discrepancy can bring about product defects.

Heat Resistance: PET material needs to be processed at high temperatures, so PET preform molds must be made from materials that can withstand such conditions. Common materials for these molds include steel alloys that can maintain their strength and durability under high temperatures.

High-Speed Production: PET preform molds are designed to operate at high speeds, producing large volumes of preforms in short amounts of time. This is particularly important for industries like bottled beverages, where demand for products is high and production efficiency is key.

Complex Mold Design: A typical PET preform mold is designed with multiple cavities to produce several preforms simultaneously. The mold design often includes sophisticated cooling systems to ensure that the preforms are rapidly cooled and hardened to avoid distortion.

Energy Efficiency: With the growing emphasis on sustainability, modern PET preform molds are designed to be energy-efficient. They use advanced heating and cooling systems to minimize energy consumption during production.

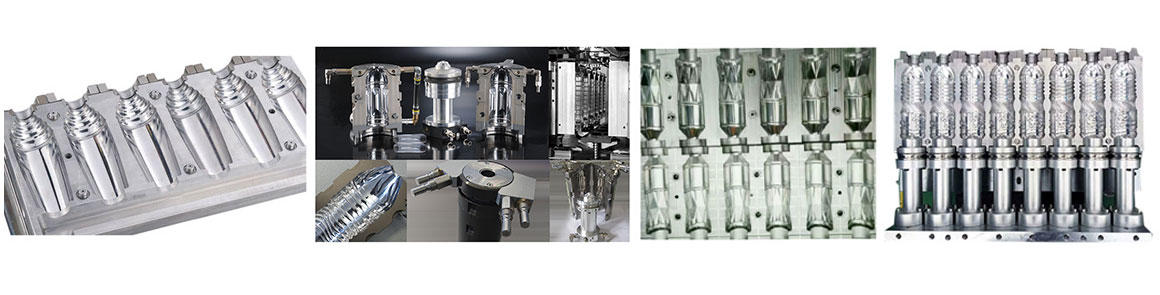

Blowing molds are molds used in the blow molding process, a manufacturing method for producing hollow plastic parts, primarily bottles and containers. Unlike other molding techniques, such as injection molding, blow molding utilizes air pressure to form the shape of the product. This process involves three primary stages: extrusion, molding, and cooling.

Extrusion Blow Molding: In this process, a tube of molten plastic, known as a parison, is extruded and then placed into a mold. Air is blown into the parison, causing it to expand and take the shape of the mold. This method is commonly used for producing bottles, jugs, and containers with simple shapes.

Injection Blow Molding: This process combines both injection molding and blow molding. A preform is produced using injection molding. The preform is then inserted into a blow mold, where air is used to expand it into the final shape. Injection blow molding is often used for smaller containers with more intricate shapes.

Taizhou Huangyan Yongsheng Mould Co., Ltd. is famous China Preform PET Mould Manufacturers and Preform PET Mold factory, founded in 2011, is located at Zhejiang province china mould town Huangyan. beautiful surrounding, convenient traffic, superior geography location. close to the nearby Hangzhou and Ningbo port, we are specializing in the development, Needle valve preform molds, various cap molds, automatic flip molds, medical injection molds, packaging molds, pipe fitting molds, bottle blowing molds, household molds, etc. We are adopting the world advanced designing software of CAD/UG/VT/ST, and we have had first-class experts and production machines.

Polyethylene Terephthalate (PET) has been a popular material in the packaging industry for decades due to its clarity, strength, and chemical resistan

Plastic injection moulding is one of the widely used manufacturing processes for producing plastic parts, ranging from small components to large, intr

The medical industry has long required packaging solutions that meet stringent hygiene, safety, and functional standards. With the increasing demand f

Medical syringes are essential instruments in healthcare, used for administering medications, vaccines, and drawing fluids. The production of medical

Automatic Flip Top Cap Mould Manufacturing Exporter Producer One of the important features of the automatic flip top cap mould is its ability to produ