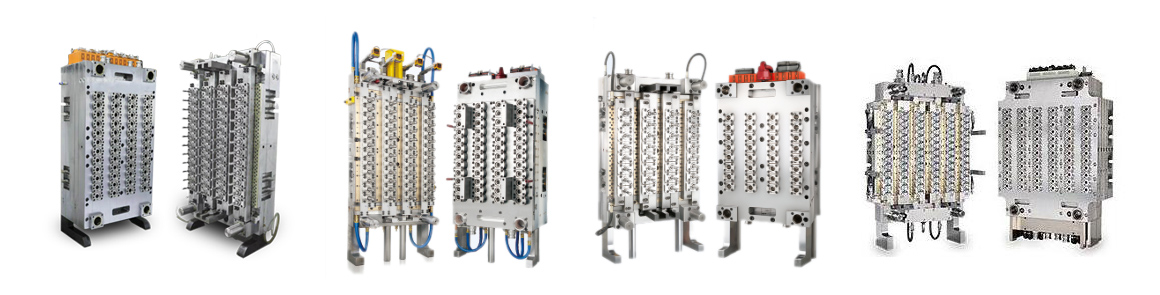

Eternal life pursues the highest mold performance. Produce high quality preforms and use corrosion resistant steel to optimize preform production. Yongsheng mold has a long life. The mold design guarantees quick and easy maintenance. Yongsheng molds are easy to use, and regular maintenance work can be done directly on the machine in the shortest possible time. Mold parts are easy to replace and can produce different preforms on the same mold. Hard mold parts guarantee mold life and minimize maintenance. We can produce PET preform mould, PET tube blank mould, 72 cavity preform mould, 48 cavity preform mould, 32 cavity preform mould, 24 cavity preform mould, 16 cavity preform mould, 12 cavity preform mould, 8 Cavity preform mold, 4-chamber preform mold, 72-tube blank tool, 48-tube blank mold, 32-cavity tube blank mold, 24-cavity tube blank mold, 16-cavity tube blank mold, 12-cavity tube blank mold, 8-cavity Tube also mold, 4-cavity tube blank mold. At present, there are three series of PET preform molds, including double lock pneumatic needle valve tube blank mold. Double lock adjustable eccentric pneumatic needle valve preform mold, ordinary no-gate preform mold. The company uses advanced CAD for mold-assisted design. The shape of the preform is optimized for the final plastic bottle to ensure the final plastic molding quality. The double-lock pneumatic needle valve tube blank mold and the double-lock adjustable eccentric pneumatic needle valve preform mold adopt multi-dimensional cone positioning system to ensure the plastic thickness of the plastic bottle is consistent. At the same time, the unique hot runner system of Yongsheng Mould ensures the same pressure and PET flow ratio of each cavity.

Taizhou Huangyan Yongsheng Mould Co., Ltd. is professional China preform mould Suppliers and preform mold company, founded in 2011, is located at Zhejiang province china mould town Huangyan. We committed to the shortest possible time to domestic and foreign customers with high quality, competitive preform mould designing. Adhere to the "quality orientation, customer priority, integrity-based" approach, innovative technology, product innovation, enterprise sustained, rapid and healthy development. We have a highly qualified technical team, gather a group of young and dynamic industry members, they are full of hands-on experience with creativity, always make unremitting efforts to target higher demands on themselves. The company constantly improve their own management and upgrade technology research and development capabilities, while promoting the development of China's mold industry.

Polyethylene Terephthalate (PET) has been a popular material in the packaging in

Plastic injection moulding is one of the widely used manufacturing processes for

The medical industry has long required packaging solutions that meet stringent h

Medical syringes are essential instruments in healthcare, used for administering

Automatic Flip Top Cap Mould Manufacturing Exporter Producer One of the importan

Automatic Flip Top Cap Mould Maker in China Wholesaler Unlike manual molding tec

OEM Automatic Flip Top Cap Mould Company For Sale Price The primary function of