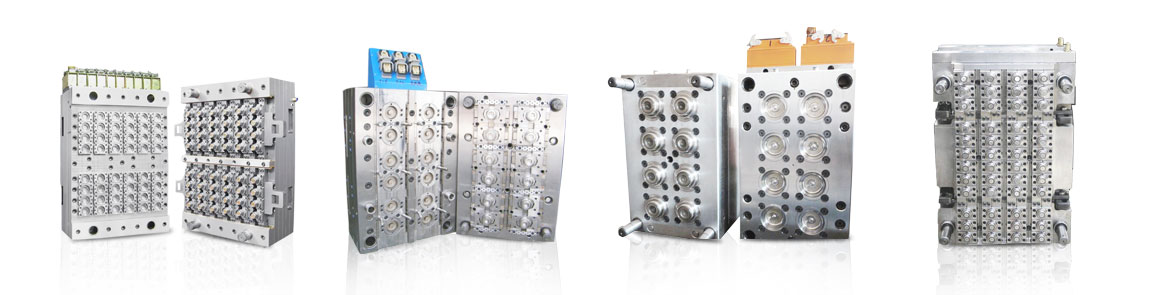

Bottle cap mold. - Bottle cap

Used for 1 step injection molding. This is size of plastic cap at 28mm 30mm 38mm 48mm 55mm . There are two kinds of it: one is PE foam lining or TPR/TPE lining, and the other is water stop ring. The foam lining helps to make these lids more tightly sealed against chemical resistance. These plastic caps do not contain bisphenol A. It is safe for consumers and the environment. The size of Lid with water stop ring at 28mm 30mm 38mm 48mm 55mm. Plastic lid is used to hold water and juice bottles, also used for hot filling bottles.

The lid is divided into anti-theft ring and no anti-theft ring, anti-theft ring can be divided into a mold directly to make the slider structure, there is a later stage (incision machine) cut out the anti-theft ring. Anti-theft ring has inside anti-theft and outside anti-theft. The inner anti-theft ring is also divided into a diameter anti-theft and folding inner ring (need folding machine). The lid will be a lot of fine differentiation, small details to distinguish more, a variety of styles.

Taizhou Yongsheng Mould Co., Ltd. can produce cap molds within 64 cavities. The hot runner or cold runner structure can be selected according to customer requirements.

The hot runner of the cap mold adopts the foreign common PE (polyolefin) non-gate hot runner design, the spring type electric heating coil is heated inside the copper tube, the hot runner nozzle separately controls the temperature, and the mold is produced under the automatic condition without the staff. Frequent operations to reduce the labor of workers. The key parts of the mold (core, cavity, slider) are made of German mirror anti-rust steel and heated (HRC45) to ensure the service life of the mold and the quality of the bottle. And the machining center is used to ensure the processing quality of the parts and achieve mutual matching. The process is stable and the effect is good, which is comparable to imported molds.

Taizhou Huangyan Yongsheng Mould Co., Ltd. is professional China cap mould Suppliers and cap mold company, founded in 2011, is located at Zhejiang province china mould town Huangyan. We committed to the shortest possible time to domestic and foreign customers with high quality, competitive cap mould designing. Adhere to the "quality orientation, customer priority, integrity-based" approach, innovative technology, product innovation, enterprise sustained, rapid and healthy development. We have a highly qualified technical team, gather a group of young and dynamic industry members, they are full of hands-on experience with creativity, always make unremitting efforts to target higher demands on themselves. The company constantly improve their own management and upgrade technology research and development capabilities, while promoting the development of China's mold industry.

Polyethylene Terephthalate (PET) has been a popular material in the packaging in

Plastic injection moulding is one of the widely used manufacturing processes for

The medical industry has long required packaging solutions that meet stringent h

Medical syringes are essential instruments in healthcare, used for administering

Automatic Flip Top Cap Mould Manufacturing Exporter Producer One of the importan

Automatic Flip Top Cap Mould Maker in China Wholesaler Unlike manual molding tec

OEM Automatic Flip Top Cap Mould Company For Sale Price The primary function of