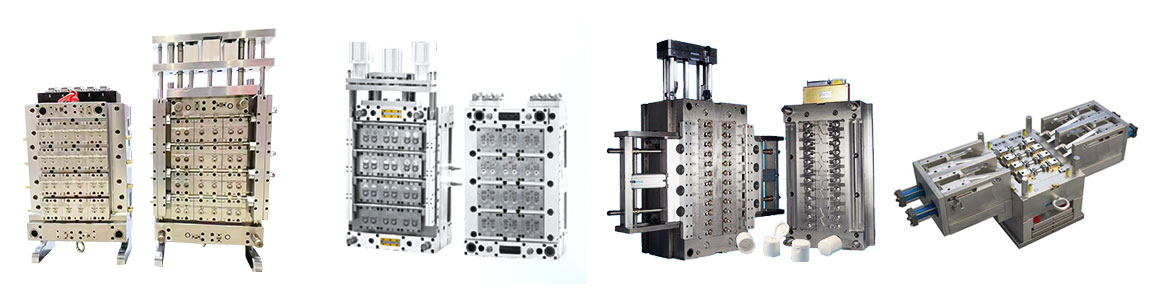

Valve gate hot runner Hydraulic actuated auto unscrewing mechanism Multi-stage ejection Packaging application All the heating elements of the mould is adopted high quality famous brand from well-known supplier in domestic market or Over-sea market. Moving part with high precise machining to make sure be interchangeable.

Mould different part apply different steel, Main adopted mould steel are S136,W302, Dc53, SKD11, Berylium Copper etc. Point to point individually control the mold hot runner system.

We have significant experience in the manufacture of cap molds for diferent types of closures by customer's demand.

Adopt imported P20,2316 etc, steel.

Hot runner is designed advanced and reasonably, each cavity heat controlled independently.

temperature uniform.

Each cavity and core have independent cooling system, shorten production cycle time.

Cavity can be changed, convenient to change remark of the cap.

Generally used for food soy sauce, vinegar, glass bottles and PET plastic bottles on the lid, the center of the lid has two kinds of tear and non-tear. There is the toiletries LDPE bottle, PP bottle, HDPE bottle of various shapes on the bottle flap, from oval, round large and small size. The first use of flip cover is to suit the beautiful shape of the bottle, but to facilitate the opening and closing of the hand, which will reflect the dry feel of the flip cover joint just with the tightness of the sealing water. The screw thread of the flip cover mold structure is jacking out, and the screw thread automatically rotates on the basis of the flip cover. The mold structure is equipped with enough device to automatically flip cover, which does not require the product to come out and close the lid. The flip cover is directly closed after the injection molding of the mold. The mold saves the cost of manually closing the lid and a process. The mold needs more precise machining and reasonable design. The perfect closing action saves customers a lot of money.

Taizhou Huangyan Yongsheng Mould Co., Ltd. is professional China Automatic Flip Top Cap Mould Suppliers and Automatic Flip Top Cap Mould company, founded in 2011, is located at Zhejiang province china mould town Huangyan. We committed to the shortest possible time to domestic and foreign customers with high quality, competitive Automatic Flip Top Cap Mould designing. Adhere to the "quality orientation, customer priority, integrity-based" approach, innovative technology, product innovation, enterprise sustained, rapid and healthy development. We have a highly qualified technical team, gather a group of young and dynamic industry members, they are full of hands-on experience with creativity, always make unremitting efforts to target higher demands on themselves. The company constantly improve their own management and upgrade technology research and development capabilities, while promoting the development of China's mold industry.

Polyethylene Terephthalate (PET) has been a popular material in the packaging in

Plastic injection moulding is one of the widely used manufacturing processes for

The medical industry has long required packaging solutions that meet stringent h

Medical syringes are essential instruments in healthcare, used for administering

Automatic Flip Top Cap Mould Manufacturing Exporter Producer One of the importan

Automatic Flip Top Cap Mould Maker in China Wholesaler Unlike manual molding tec

OEM Automatic Flip Top Cap Mould Company For Sale Price The primary function of