Preventing

cap mold from forming in the first place involves controlling the moisture levels in your home and being vigilant for signs of mold growth. Here are some steps you can take to prevent cap mold:

1.Fix leaks promptly: Any sources of water intrusion, such as leaking pipes or roofs, should be repaired as soon as possible to prevent moisture from accumulating and creating a breeding ground for mold.

2.Control humidity: Keep indoor humidity levels below 60% by using dehumidifiers in damp areas such as basements, bathrooms, and kitchens. Proper ventilation in these areas is also essential.

3.Use exhaust fans: Use exhaust fans in bathrooms and kitchens to reduce moisture and humidity levels.

4.Increase airflow: Increase the amount of air circulation in your home by opening windows and using fans to improve air flow.

5.Monitor indoor moisture levels: Use a moisture meter to measure the moisture levels in your home and address any areas that exceed normal levels.

6.Clean and maintain HVAC systems: Regularly clean and maintain your HVAC system to ensure proper air flow and reduce the likelihood of mold growth.

7.Insulate and ventilate: Properly insulate and ventilate your home to prevent moisture from building up in walls and ceilings.

8.Keep surfaces clean and dry: Regularly clean and dry surfaces in damp areas such as bathrooms and kitchens to prevent mold growth.

By taking these preventative measures, you can reduce the risk of cap mold forming in your home.

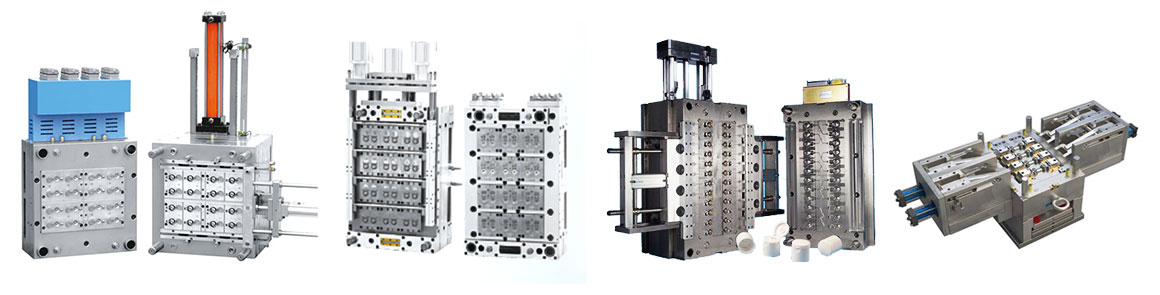

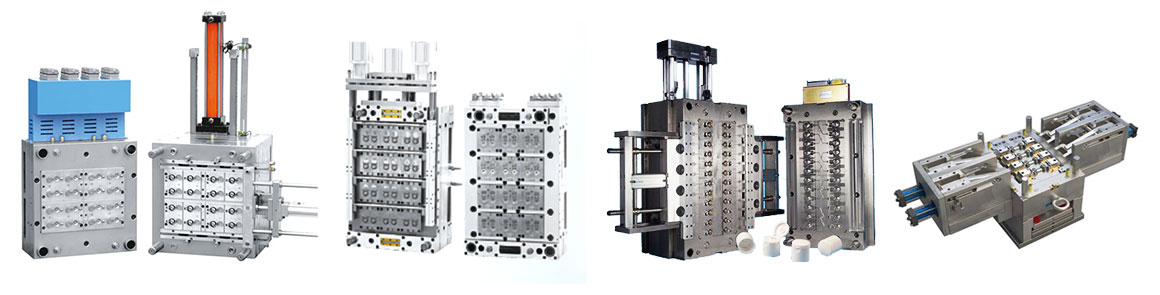

Automatic Flip Top Cap Mould

Valve gate hot runner Hydraulic actuated auto unscrewing mechanism Multi-stage ejection Packaging application All the heating elements of the mould is adopted high quality famous brand from well-known supplier in domestic market or Over-sea market. Moving part with high precise machining to make sure be interchangeable.

Mould different part apply different steel, Main adopted mould steel are S136,W302, Dc53, SKD11, Berylium Copper etc. Point to point individually control the mold hot runner system.

We have significant experience in the manufacture of cap molds for diferent types of closures by customer's demand.

Adopt imported P20,2316 etc, steel.

Hot runner is designed advanced and reasonably, each cavity heat controlled independently.

temperature uniform.

Each cavity and core have independent cooling system, shorten production cycle time.

Cavity can be changed, convenient to change remark of the cap.