Cleaning and maintaining

Preform PET mould are crucial to ensure the production of high-quality PET products. Here are some best practices for cleaning and maintaining preform PET molds:

1.Regular cleaning: Regular cleaning of the preform PET molds is necessary to prevent the buildup of resin, dust, and other debris. It is recommended to clean the molds after every production run to remove any residual material.

2.Use appropriate cleaning agents: Use appropriate cleaning agents that are compatible with PET and the mold surface. Avoid using harsh chemicals that can damage the mold surface.

3.Inspect for damage: Regularly inspect the mold for any signs of wear, cracks, or damage. Replace any damaged components immediately to prevent further damage to the mold.

4.Lubrication: Use a suitable lubricant to prevent the buildup of resin and improve the release of preforms from the mold. It is recommended to use a food-grade lubricant.

5.Temperature control: Proper temperature control is essential for the efficient production of PET preforms. Ensure that the molds are maintained at the correct temperature to prevent warping or other defects.

6.Storage: Store the preform PET molds in a clean and dry environment when not in use. Protect the molds from dust, moisture, and other contaminants.

7.Record maintenance: Maintain a record of maintenance activities performed on the preform PET molds. This record can help identify any recurring issues and ensure that the molds are maintained properly.

By following these best practices, you can ensure the efficient and reliable production of high-quality PET preforms.

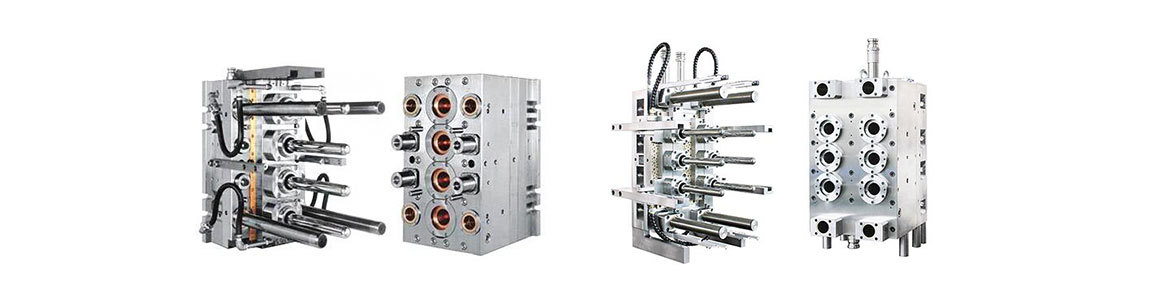

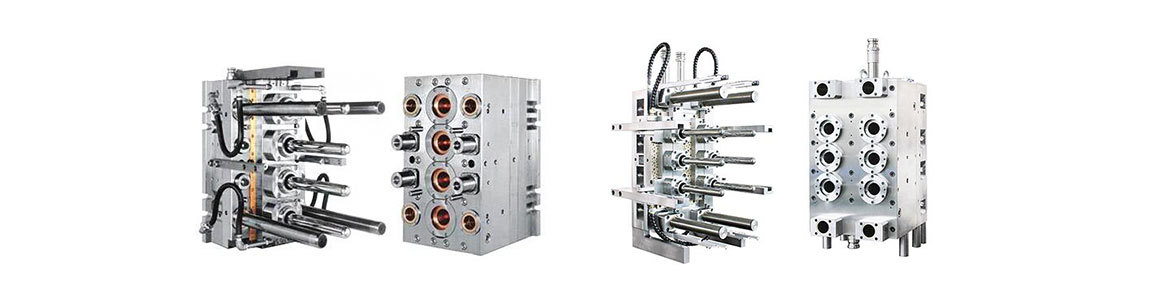

20L Wine Bottle Preform & Blowing Mould

Eternal life pursues the highest mold performance. Produce high quality preforms and use corrosion resistant steel to optimize preform production. Yongsheng mold has a long life. The mold design guarantees quick and easy maintenance. Yongsheng molds are easy to use, and regular maintenance work can be done directly on the machine in the shortest possible time. Mold parts are easy to replace and can produce different preforms on the same mold. Hard mold parts guarantee mold life and minimize maintenance. We can product 2-16 cavity 5 gallon self-lock preform mould, it can blow 20L 30L 40L 50L and more bigger bottle. At present, there are three series of PET preform molds, including double lock pneumatic needle valve tube blank mold. Double lock adjustable eccentric pneumatic needle valve preform mold, ordinary no-gate preform mold. The company uses advanced CAD for mold-assisted design. The shape of the preform is optimized for the final plastic bottle to ensure the final plastic molding quality. The double-lock pneumatic needle valve tube blank mold and the double-lock adjustable eccentric pneumatic needle valve preform mold adopt multi-dimensional cone positioning system to ensure the plastic thickness of the plastic bottle is consistent. At the same time, the unique hot runner system of Yongsheng Mould ensures the same pressure and PET flow ratio of each cavity.