The selection of materials for making

pipe fitting molds depends on various factors, such as the type of pipe fitting, the required dimensional accuracy, the number of parts to be produced, and the molding process used. Some of the commonly used materials for making pipe fitting molds include:

1.Steel: Steel is a popular choice for making molds due to its durability, hardness, and ability to withstand high temperatures. Depending on the specific application, different types of steel can be used, such as tool steel, stainless steel, or carbon steel.

2.Aluminum: Aluminum molds are lightweight, have good thermal conductivity, and are ideal for low-volume production runs. They are also relatively easy to machine and have good corrosion resistance.

3.Brass: Brass molds are commonly used for molding small pipe fittings, such as couplings and elbows. They have good thermal conductivity, are easy to machine, and offer good corrosion resistance.

4.Copper: Copper molds are ideal for molding small to medium-sized pipe fittings, such as tees and reducers. They have good thermal conductivity, are highly corrosion-resistant, and can be easily machined.

5.Plastic: For molding plastic pipe fittings, molds made from thermoplastic materials such as PVC, HDPE, or PP can be used. These molds are typically less expensive than metal molds and are easier to machine.

Ultimately, the choice of material for a pipe fitting mold will depend on various factors, such as cost, durability, and required properties of the final product.

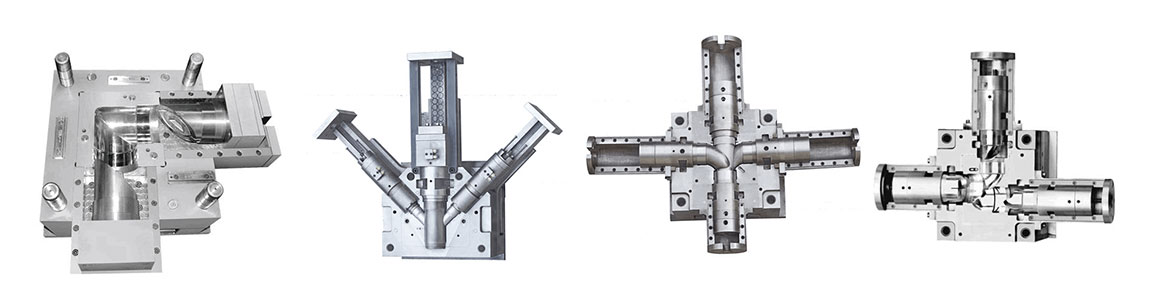

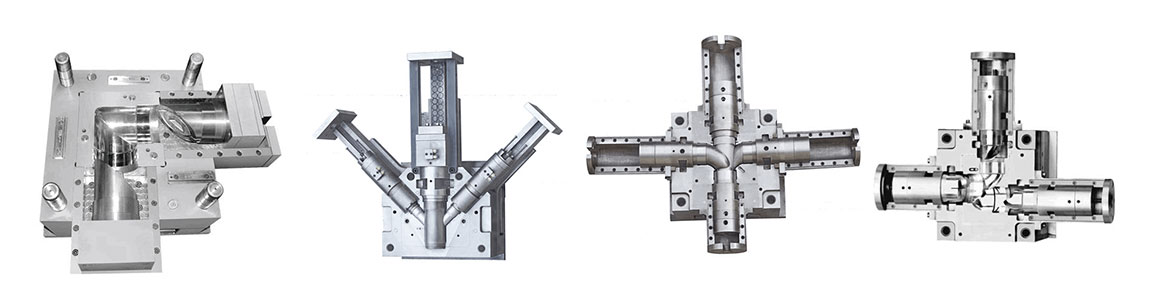

PVC Pipe Fitting Mould

Mould name: PVC Belling Pipe Fitting Mould

Mould cavity:2 cavity

Mould size:1000X1000X600 mm

Mould material: DIN 1.2316

Mould life:1,000,000 Shots Ejection system: Collapsible core system

Mould running: Fully automatic Mould features: Excellent precision control for demension tolerance and shrinkage With intensive cooling system, optimal air venting, shining polish, advanced mould design Collapsible core system make it easier to operation, Superior impact and abrision resistance for the moulds

Injection cycle time:50Seconds

Delivery time:50 days