The production of

Medical Syringe mould is an expensive and difficult process. This requires special injection moulding machines and specially designed moulds.The raw material used is polypropylene which is fed into the moulding machine and then moulded in chilled condition to get better clarity. The syringe is then assembled with the needle in automatic assembly machine and sent into sterilization plant where it is thoroughly sterilized using ethylene oxide.

Plastics are a huge part of the medical industry. They are used in almost every tool and device you can imagine, from syringes to surgical gloves.These plastics don’t harbor pathogens, are affordable and can stand up to different sterilization processes. They’re also lightweight and durable, making them a smart choice for medical equipment.The material you choose for your Medical Syringe mold is a critical factor in the quality of the final product. It’s essential to pick a material that has the proper strength properties and is FDA-approved for your application. It should also be able to withstand different temperatures, vibrations, and other environmental factors.

Designing a Medical Syringe mold involves many different steps. For example, a design for manufacturing (DFM) phase is often required in order to ensure the product will be manufacturable and compatible with injection molding machines.When designing a Medical Syringe mold, it is important to consider the part’s functionality and how it interfaces with other parts or end users. Taking these factors into consideration is important because it allows the engineering team to properly assess the design for manufacturability and develop a clear understanding of the constraints that will be placed on the final product.In addition to determining the material requirements, designers must also make sure that the injection molded parts are able to be ejected from the mold without causing damage or scratching. This requires a low to zero draft region. This can be difficult for some parts, especially if the part relies on maintaining a liquid barrier throughout its inner diameter.

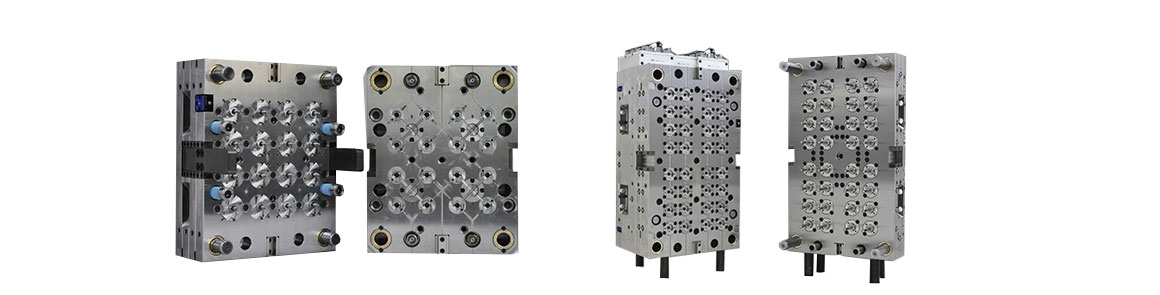

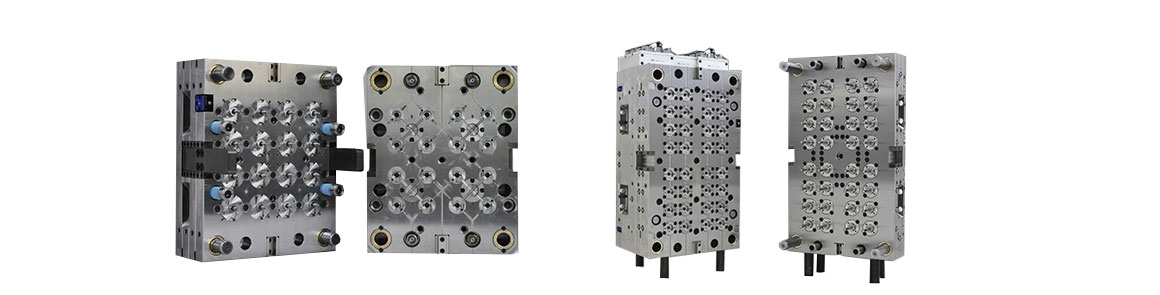

Mold making is the process of creating a mold or casting.This can be done with a variety of materials including metals and cold setting materials such as resins.The molding process involves pouring a liquid material into the mold cavity and then allowing it to cure via chemical reaction or cooling. Once the material has cured, it is then removed from the mold and the part is made.A medical syringe is a type of plastic injection molded medical device. The syringe has many functions and is designed to have a high level of accuracy.Injection molding of medical devices is an extremely complex and precise process. It requires skilled and experienced injection molding facilities in order to deliver the highest level of quality.

Injection molding is a common production process that is used to manufacture various medical plastic components. It is a seamless manufacturing process that offers high accuracy and precision.When it comes to producing Medical Syringe molds, there are many different processes available to manufacturers. It is important to understand the basics of each process so you can make informed decisions.One way to do this is to learn more about injection molding techniques. This will help you determine what the best method for your project is.Another common injection molding method is called “direct injection molding.” This process can be used to produce a variety of medical products, including syringe bodies and ampules. It is highly efficient and can be done at a low cost. It is a process that can be automated to reduce the risk of errors. It also allows for faster turnaround times. This makes it a popular choice for companies looking to fabricate syringes and ampules for the medical industry.

PET Test Tube Mould

We can produce: medical supplies molds, medical plastic molds, medical equipment molds, disposable blood transfusion, liquid appliance injection molds, medical drop bottle molds, medical bottle molds, health care bottle molds, laboratory supplies molds, medical test tube molds, Medical molds, pharmaceutical preform molds, pharmaceutical bottle cap molds, medical plastic packaging molds, sheath stripping molds, large needle sleeve molds, needle holder large core molds, long cavity molds, needle holders, strip molds, protection Set of pull sleeve mold, sheath gate mold, needle seat needle mold, vibration small core mold, pull rod mold, sheath mold, needle seat cavity mold, needle seat mold.