Preform PET mould are used in the production of PET (Polyethylene terephthalate) bottles. They are essentially small plastic tubes with threaded necks that are heated and stretched to form the final shape of a bottle. PET preforms are used to produce a wide range of containers, including water bottles, soft drink bottles, juice bottles, and many more.

The PET preform is typically made through an injection molding process, where molten PET material is injected into a mold and then cooled to form a solid tube with a neck and a thread. This tube is then reheated and stretched to form the final shape of the bottle.

PET preforms offer several advantages over other materials, including lightweight, durability, and the ability to hold carbonated beverages without losing their shape or integrity. They are also highly recyclable and can be reused in the production of new PET bottles or other plastic products.

In summary, PET preforms are an essential component of the manufacturing process for PET bottles and offer numerous benefits over other materials.

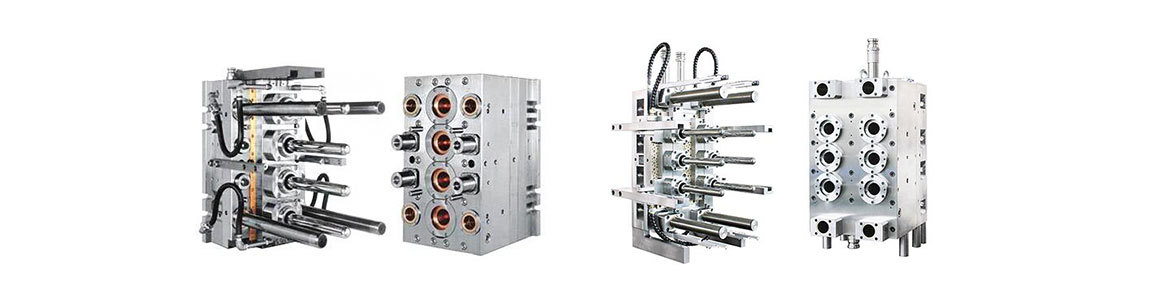

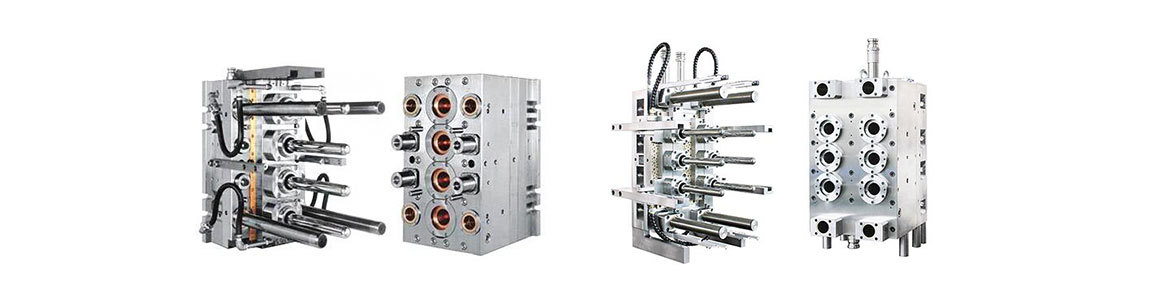

20L Wine Bottle Preform & Blowing Mould

Eternal life pursues the highest mold performance. Produce high quality preforms and use corrosion resistant steel to optimize preform production. Yongsheng mold has a long life. The mold design guarantees quick and easy maintenance. Yongsheng molds are easy to use, and regular maintenance work can be done directly on the machine in the shortest possible time. Mold parts are easy to replace and can produce different preforms on the same mold. Hard mold parts guarantee mold life and minimize maintenance. We can product 2-16 cavity 5 gallon self-lock preform mould, it can blow 20L 30L 40L 50L and more bigger bottle. At present, there are three series of PET preform molds, including double lock pneumatic needle valve tube blank mold. Double lock adjustable eccentric pneumatic needle valve preform mold, ordinary no-gate preform mold. The company uses advanced CAD for mold-assisted design. The shape of the preform is optimized for the final plastic bottle to ensure the final plastic molding quality. The double-lock pneumatic needle valve tube blank mold and the double-lock adjustable eccentric pneumatic needle valve preform mold adopt multi-dimensional cone positioning system to ensure the plastic thickness of the plastic bottle is consistent. At the same time, the unique hot runner system of Yongsheng Mould ensures the same pressure and PET flow ratio of each cavity.