In recent years, with the rapid development of China's automobile industry, 3C, home appliances, medical, building materials and other industries, the medical mold processing industry has achieved rapid development. Among them, sophisticated mold equipment and high-quality cutting tools provide a powerful help for the rapid development of the mold industry. The intelligence of mold equipment and the innovation of tool structure are becoming more and more important in the improvement of mold processing quality and the development of high quality.

The requirements for medical molds are really high. The main production standards are reflected in the products. For example, many medical products are equipped with Luer connectors. This is a production standard. If the mold factory does not understand this standard, it will be very troublesome. The size of many products has national standards. The mold standard is mainly in automated production, multi-cavity, no burr flash, China, especially in contact with blood or human body, may cause medical accidents. After understanding the above requirements, we can start manufacturing medical injection molds. We also need high-standard mold designers and high-precision processing technology and manufacturing concepts to do a good job.

Medical mold manufacturers are particularly important for the control of processing accuracy, because the needle products of the puncher are small, the size of the small hole is only 1mm, and the concentricity of the core is guaranteed, which is a great test for the accuracy of the mold processing machine and processing equipment . When selecting processing equipment, choose imported high-speed lathes, and try to choose equipment that has been used for less than 5 years, because the actual processing accuracy of the equipment for many years has deviations, which will directly affect the molding of the product.

The needle should be made of copper electrode, which is not easy to wear. After high-speed and precise engraving is in place, the mold is hit in place with a mirror spark.

Today, thermoplastics have become the dominant material in manufacturing, replacing steel in many applications.

Thermoplastics are very durable and suitable for long-life applications. Industry can now use this valuable material for 3D printing, expand the use of thermoplastics, and gain design freedom that exceeds traditional manufacturing limits.

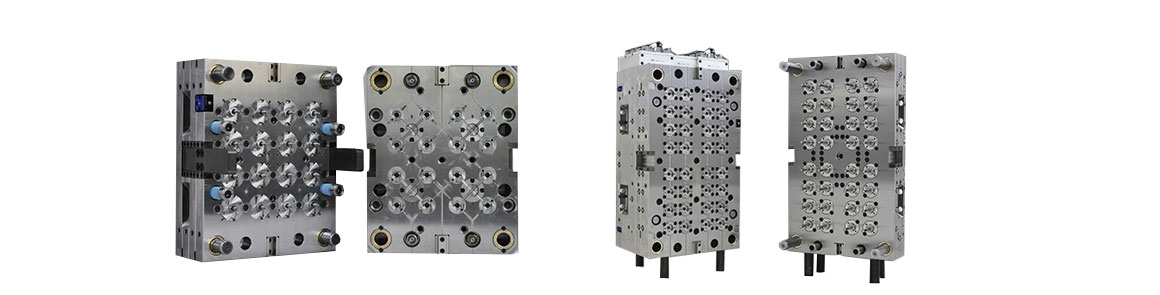

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto