There are many types of plastic molds. According to the different pouring systems, plastic molds can be divided into three types. Which three types are they?

1. Fine nozzle mold: runners and gates are not on the parting line, but are usually directly on the product. Therefore, it is necessary to design an additional set of nozzle parting lines. The design is more complicated and the processing is more difficult. Generally, the thinner should be selected according to the product requirements. Water mouth system. The fixed part of the nozzle mold is generally composed of three steel plates, so this type of structural mold is also called the "three-plate mold". The three-plate mold is the simplest structure in the nozzle mold.

2. Large nozzle mold: Large nozzle mold means that the gate and runner are on the parting line. When the mold is opened, it is demolded together with the product. The design is the simplest, easy to process, and low cost, so many people use large nozzle molds. The plastic mold structure is divided into two parts: the movable mold and the fixed mold. The movable part of the injection molding machine is a movable mold (mostly on the ejection side), and the injection end of the injection molding machine is generally inactive and called a fixed mold. Because the fixed mold part of the large nozzle mold is generally composed of two steel plates, this type of structural mold is also called "two-plate mold". The simplest structure in the large nozzle mold is the two-plate mold.

3. Hot runner mold: The structure of this type of mold is roughly the same as the nozzle. The biggest difference is that the runner is located in one or more hot runner plates and hot nozzles with constant temperature. There is no cold material demoulding, runners and gates. It is directly on the product, so the runner does not need to be demolded. This system is also known as a nozzleless system, which can save raw materials and is suitable for situations where raw materials are more expensive and products are demanding. Design and processing are difficult, and mold costs are high.

The hot runner system is mainly composed of a hot sprue sleeve, a hot runner plate, and a temperature control electric box. Our common hot runner system has two forms: single-point hot gate and multi-point hot gate. The single-point hot gate uses a single hot sprue sleeve to directly inject the molten plastic into the cavity. It is suitable for plastic molds with a single cavity and single gate; the multi-point hot gate branches the molten material to each The sub-heat sprue sleeve then enters the cavity. It is suitable for single cavity multi-point feeding or multi-cavity molds.

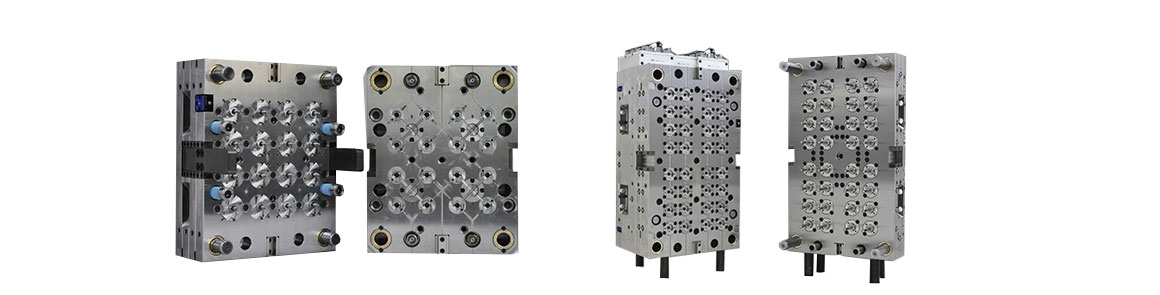

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto