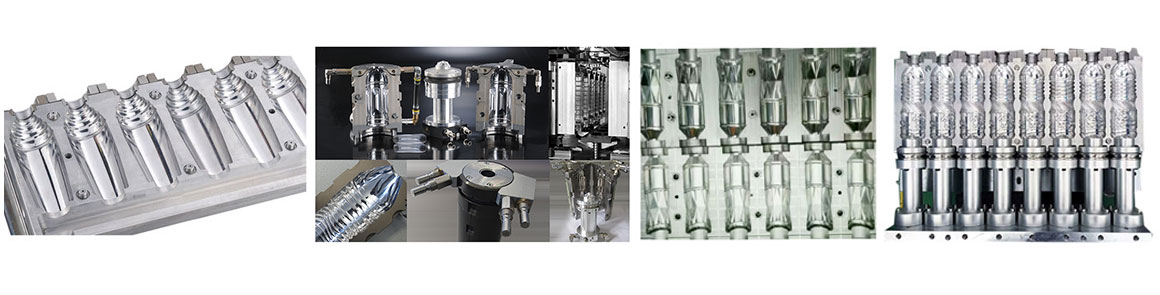

Injection blow moulding is basically a series of processes involved in making hollowed plastic molding products and components. this injection blow molding process is one of the best molding processes for thin wall plastic molding containers. The three major processes are:

Injecting a parison or thermoplastic into a blow mold to create a perform pipe at first (parison).

Moving the perform pipe to blow mold and blowing the thermoplastic into a mold’s cavity to form a hollow molding part,

Ejecting the final product. A wide range of hollowed injection molding products can be achieved through this method such as plastic bottles.

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto