High-output PET preform molding systems are very efficient for manufacturing large numbers of identical parts. When more than one preform is required to make different bottles, it may seem that multiple lower-output molding systems and multiple molds are required.

But the combined advantages of high-output systems and the liberty to change production from one preform to another can be achieved in some cases by careful planning of mold-change parts, together with the required modifications of the preform designs. The same upfront planning can cut costs and improve results when converting a mold.

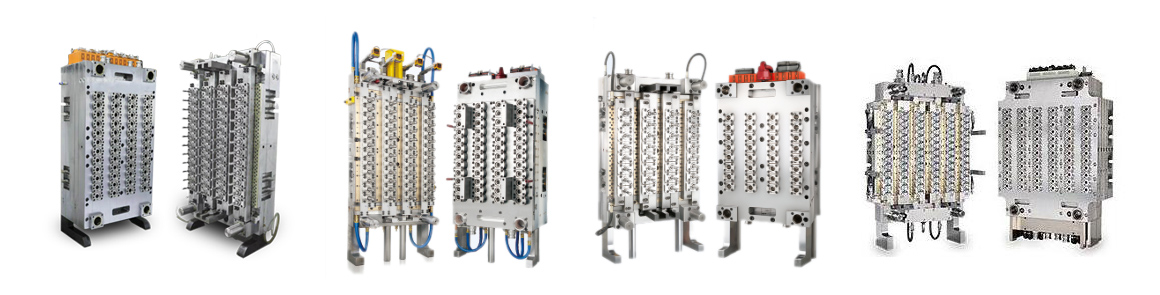

Two molds for quite different preforms can share interchangeable parts. For example, changes in the weight of the preform to make different sizes of similarly shaped bottles can be accomplished with a new set of cores, if the original preform design is suitable.

Moreover, different neck finishes can be produced with interchangeable neck rings, allowing you to vary the thread finish. This is assuming the preform and mold design permit you to choose the placement of the split line.

But adding modularity should not be an afterthought. Features to permit varying the dimensions of the preform and changing the mold cores, cavities, neck rings and gate inserts should be considered with new tooling acquisitions rather than after the mold has been built.

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto