The maintenance personnel who are responsible for the daily maintenance of the mold must work carefully and carefully to ensure the best condition of the mold, and it has been expected to be effective and economical during production, and to reduce the manufacturing cost as much as possible. So how to complete the maintenance of the mold! Let’s learn with the editor below!

First of all, the maintenance instructions: when the injection mold is maintained, the parts need to be checked according to the drawings. Even if there is no special instruction, it must be checked when entering the warehouse; it is not allowed to modify the size of the mold parts that do not meet the drawings, or use spacers or gaskets for additional insertion, etc.; mold maintenance after the production order is completed , Must refer to the problem points provided by the production department, production department records and the final product; in the mold maintenance, if a major problem is found, it should immediately report to the supervisor and wait for instructions.

Secondly, the specific requirements for the maintenance of injection molds: when replacing mold parts, confirm that the quality of the replaced parts is qualified; disassemble and assemble each part to be tapped and slowly pressed; when assembling mold inserts, confirm that the fit gap is qualified; avoid the surface of the part No curls, scratches, pits, dross, defects, rust, etc.; if there are parts replacement, communicate and confirm with the mold design department in time. Before and after disassembly of the mold, pay attention to maintaining the balance of each part; if necessary, replace Parts must be replaced in time.

Finally, the daily maintenance of the injection mold must be carried out carefully and carefully to ensure that the mold is kept in the best condition at all times.

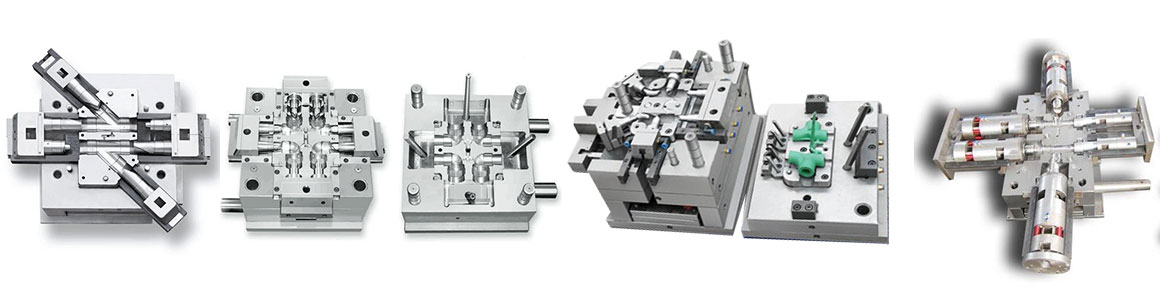

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto