Preform PET moulds are typically made from high-quality tool steel, which is a high-strength alloy that can withstand high temperatures and pressures during the injection molding process. The most common types of tool steel used for preform PET moulds are:

1.P20: This is a low-carbon, high-alloy steel that is easy to machine and has good toughness and wear resistance.

2.H13: This is a high-carbon, high-chromium steel that is known for its excellent heat resistance, toughness, and wear resistance.

3.S136: This is a stainless steel that is highly corrosion-resistant and has good wear resistance and toughness.

4.NAK80: This is a pre-hardened steel that is highly machinable and has good wear resistance and toughness.

In addition to tool steel, some preform PET moulds may also incorporate other materials or coatings to enhance performance, such as:

1.Hard chrome plating: This is a process in which a layer of chrome is electroplated onto the surface of the mould to improve wear resistance and prevent corrosion.

2.Nitriding: This is a process in which the surface of the mould is hardened by exposing it to nitrogen gas at high temperatures, which improves wear resistance and reduces the risk of cracking.

3.Ceramic coatings: These are thin layers of ceramic material that are applied to the surface of the mould to reduce friction and improve release properties.

Overall, the choice of materials for preform PET moulds will depend on factors such as the desired level of durability, precision, and cost. High-quality tool steel is the most commonly used material due to its excellent performance and reliability.

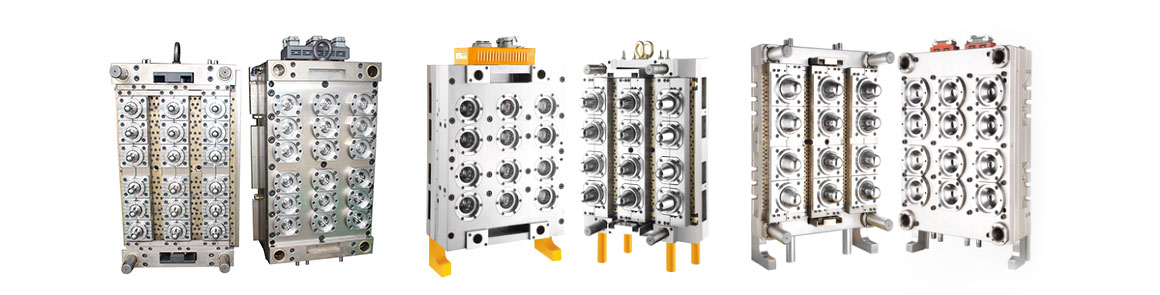

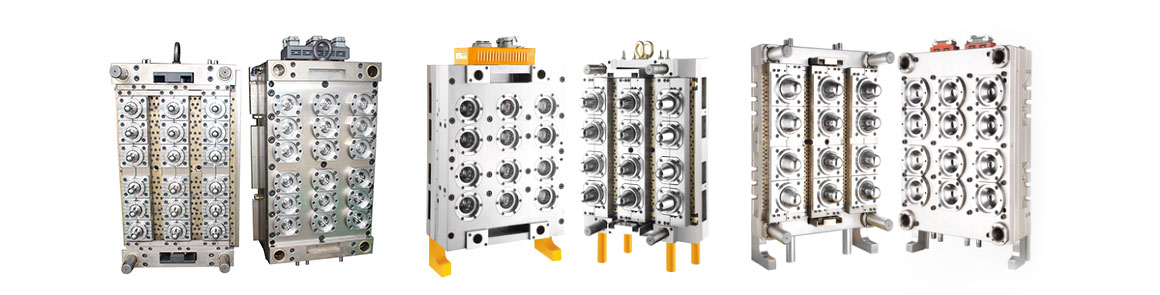

Wide mouth preform mould

Eternal life pursues the highest mold performance. Produce high quality preforms and use corrosion resistant steel to optimize preform production. Yongsheng mold has a long life. The mold design guarantees quick and easy maintenance. Yongsheng molds are easy to use, and regular maintenance work can be done directly on the machine in the shortest possible time. Mold parts are easy to replace and can produce different preforms on the same mold. Hard mold parts guarantee mold life and minimize maintenance. We can product 80-300mm,4-32 cavity self-lock width preform mould.At present, there are three series of PET preform molds, including double lock pneumatic needle valve tube blank mold. Double lock adjustable eccentric pneumatic needle valve preform mold, ordinary no-gate preform mold. The company uses advanced CAD for mold-assisted design. The shape of the preform is optimized for the final plastic bottle to ensure the final plastic molding quality. The double-lock pneumatic needle valve tube blank mold and the double-lock adjustable eccentric pneumatic needle valve preform mold adopt multi-dimensional cone positioning system to ensure the plastic thickness of the plastic bottle is consistent. At the same time, the unique hot runner system of Yongsheng Mould ensures the same pressure and PET flow ratio of each cavity.