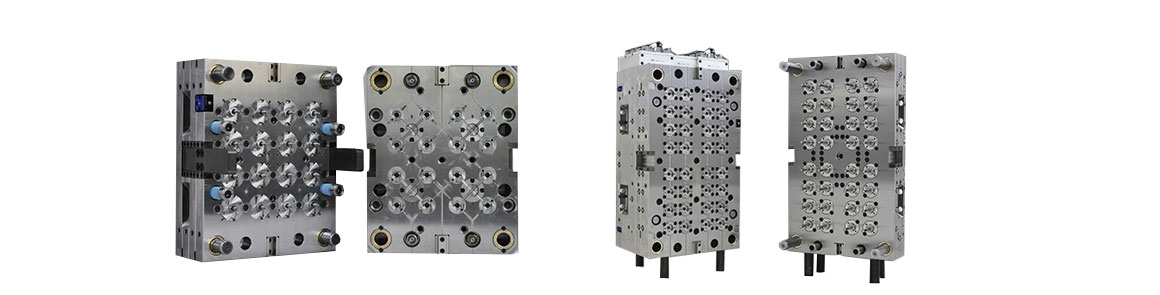

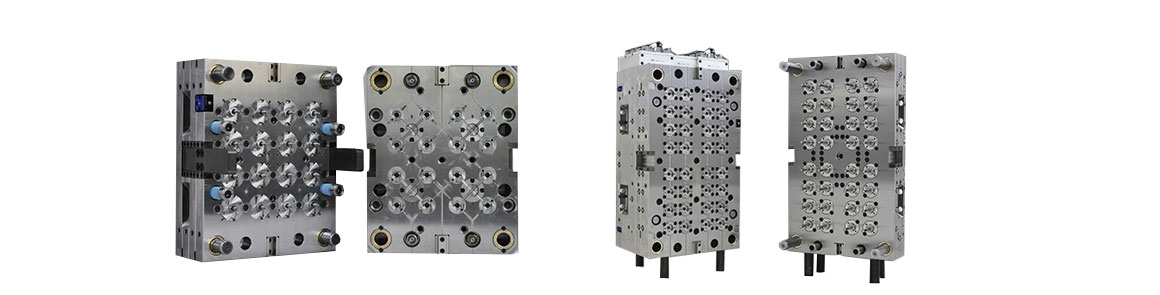

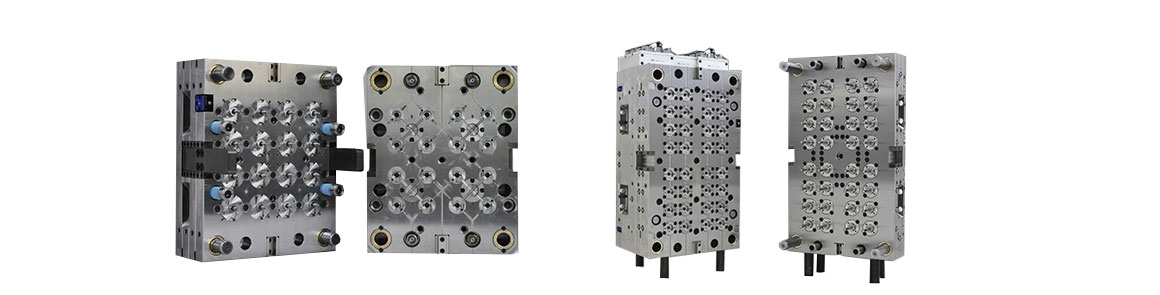

PET test tube moulds play a crucial role in the precision and efficiency of laboratory equipment production. These moulds are specifically designed to produce test tubes made from PET (Polyethylene Terephthalate) plastic, a material widely used in the manufacturing of laboratory consumables. The use of high-quality PET test tube moulds offers several benefits that contribute to the overall production process. Here are some ways PET test tube moulds ensure precision and efficiency:

Accurate and Consistent Results: PET test tube moulds are engineered with precision to ensure accurate and consistent production of test tubes. They are designed to create uniform dimensions, wall thickness, and shape for each test tube, resulting in consistent and reliable laboratory equipment. This precision is crucial for compatibility with automated laboratory processes and accurate sample analysis.

High-Quality Finishing: PET test tube moulds are made with high-quality materials and manufacturing techniques, allowing for smooth and precise finishing of the test tubes. The moulds ensure that the test tubes have smooth inner and outer surfaces, free from imperfections or irregularities. This high-quality finishing facilitates easy handling and reduces the risk of contamination during sample preparation and analysis.

Increased Production Efficiency: PET test tube moulds are designed for high-speed production, allowing for efficient manufacturing processes. The moulds enable the production of multiple test tubes simultaneously, reducing production time and increasing overall output. This efficiency is particularly beneficial for large-scale laboratory equipment production or when there is a need for a high volume of test tubes.

Longevity and Durability: PET test tube moulds are made from durable materials that can withstand the demands of repeated use and high-speed production. The moulds are designed to resist wear and tear, ensuring a longer lifespan and consistent performance over time. This durability reduces the need for frequent mould replacements, contributing to cost savings and uninterrupted production.

Compatibility with PET Plastic: PET test tube moulds are specifically designed for PET plastic, which offers several advantages in laboratory settings. PET is transparent, allowing for easy visual inspection of samples. It is also chemically resistant, making it suitable for various laboratory applications. The moulds are engineered to work seamlessly with PET plastic, ensuring optimal material flow and adherence to the mould design.

Customization Options: PET test tube moulds can be customized to meet specific requirements and preferences. They can be designed to produce test tubes of different sizes, shapes, and configurations based on the intended laboratory applications. Customization options allow for versatility in laboratory equipment production, catering to diverse research needs.

Quality Control and Regulatory Compliance: PET test tube moulds play a vital role in ensuring consistent quality control and adherence to regulatory standards. The precise design and production process of the moulds contribute to the production of test tubes that meet the required specifications and regulatory guidelines. This is crucial for maintaining the integrity of laboratory experiments, research, and sample analysis.

In summary, PET test tube moulds offer precision and efficiency in laboratory equipment production. They ensure accurate and consistent results, high-quality finishing, increased production efficiency, longevity and durability, compatibility with PET plastic, customization options, and compliance with quality control and regulatory standards. By utilizing high-quality

PET test tube moulds, manufacturers can optimize their production processes and deliver reliable and precise laboratory equipment for various scientific and research applications.