One thing Preform PET mould you should always pay attention to is the crystallization of the material, which is the largest part of shrinkage. And this kind of crystallization is not only affected by the manufacturing process but also restricted by the machine and injection mold. Similarly, the filler in the material will also have a great influence on the crystallization. Also keep in mind that post-processing shrinkage can also cause crystallization, which in turn causes the injection mold to shrink.Not every part has a uniform wall thickness, which can cause uneven shrinkage.

Likewise, so-called amorphous thermoplastics are not 100% amorphous and therefore may shrink, depending on the overall conditions mentioned above. Both are highly developed and powerful products. Which one is much better than no process calculation at all. In this sense, you can't go wrong with any one you choose. That's the same, because it will be difficult to answer questions in a truly informed manner. Under industrial conditions, almost no one can use both systems proficiently.

Unless you really pursue the use of high-quality mold steel, China's injection molds will shine in water and mold steel. I have seen that plastic injection molds in China do deform in the press because their injection molds are made of lead and soft. I have seen well-made Chinese molds, but again, the materials used are still substandard. Communication delays are also a continuing problem. This is one of the reasons why I use the United States, the United Kingdom or Italy in China-don't worry about anything mentioned earlier.

The only reason why Chinese injection molds maintain more competitive prices is that the country pegs its currency to the US dollar, so you will never see the real cost. In the near future, the Chinese will not be able to continue pegging their currency to the U.S. dollar, especially when the U.S. dollar is wasted by our own government, by following proper part design, sink marks can be minimized. If there are any ribs or structural features behind the "A" shaped surface, the dents will not be eliminated. But with proper part design, it can be minimized to an invisible degree.

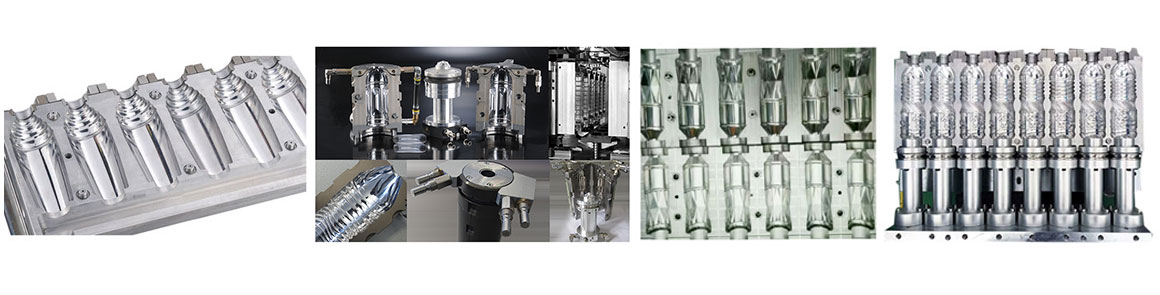

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto