When the plastic mold is processed, the plastic is brought into the Medical Syringe mould except for the heat radiation and the heat flow out of the mold. Most of the heat is carried out of the mold by the circulating heat transfer medium through heat conduction. The heat transfer medium includes water, oil.

The temperature of the plastic mold is generally controlled by adjusting the temperature of the heat transfer medium, adding heat insulation boards and heating rods.To reduce the mold temperature, it is generally achieved by passing warm water about 25 degrees to the fixed mold and "chill water about 4 degrees to the moving mold. When the channel of the heat transfer medium, that is, the cooling water channel, cannot pass through other parts, materials with better heat transfer efficiency should be used to transfer the heat to the heat transfer medium.

To increase the temperature of the mold, it is generally achieved by passing hot water into the cooling water channel and heating by the hot water machine. When the mold temperature is high, an electric heating rod can be used for heating.

For molds that need to be heated, to prevent heat loss due to heat conduction, a resin insulation board should be added to the mold panel.In the hot runner mold, the hot runner plate has a high temperature requirement and must be heated by a heating rod. In order to avoid the heat of the hot runner plate from being transferred to the fixed mold, it will be difficult to cool the fixed mold. Therefore, the contact surface with the fixed mold should be minimized during design. And use heat insulation sheet for heat insulation.

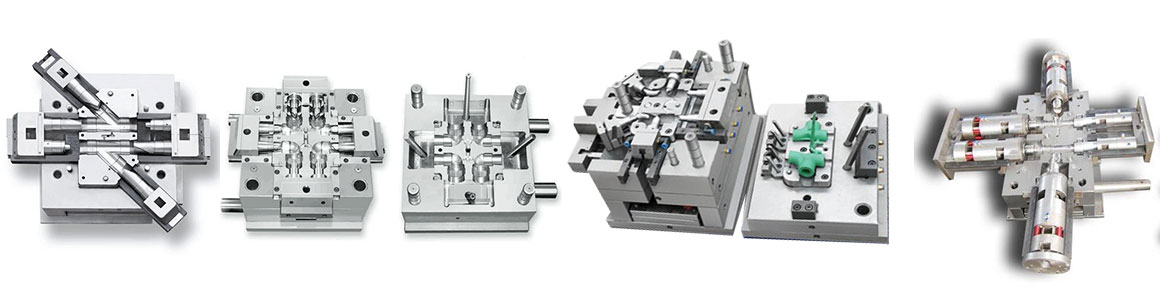

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto