The mold itself is specialized tooling that is created uniquely for each part type to be produced.

Mold making is an integral part of the plastic injection molding process. Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts.

To be honest, blow molding of containers for food products or cleaning products is a little more complex because the bottles often begin with an injection molded neck that is threaded with parasin attached. The parasin mold that produces the neck does well when high diamond polished and then flash chromed.

In addition, the neck ring inserts that actually form the threads are made from steel and tend to wear. When that happens, micro welding them for repair, followed by polishing and chrome plating to re-establish the original surface properties, has been very successful.

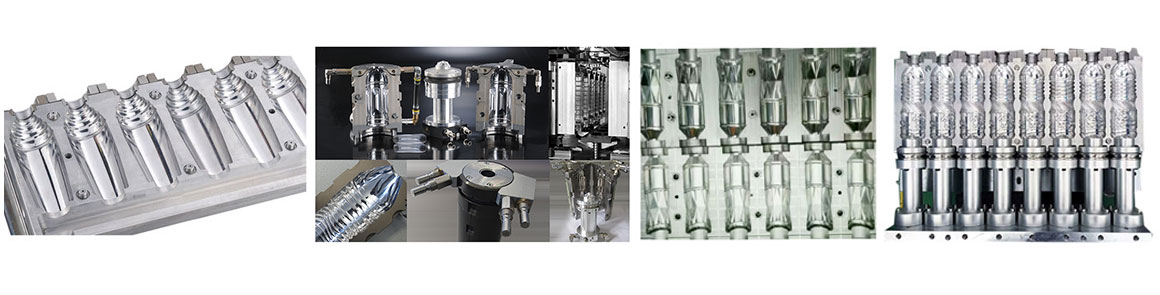

Once the parasin is formed during the injection molding process, it is then transferred to a blow mold to form the bottle. Blow molds are typically made from aluminum and require a high diamond polish to aid lubricity and part appearance. Like most molds, they also require periodic maintenance.

Mold material: S136H 、718H、NAK80、 P20、2738、8407、SKD61、H13Mould cavity number: single cavity, multi cavityProcessing accuracy: 0.05mmMold

We have ISO9001 international quality management system and experience in controlling production costs in China. Therefore, we can help you save 20% -

Mold material: S136 HRC48-52Manufacturing process: CNC milling, CNC machining, EDM/wire cuttingWe are equipped with the world's top precision machinin

Our liquid transfer gun suction head medicine mould is made of high-quality materials as a whole. There are no burrs at the tip and mouth of the produ

The mold has a short injection cycle, high efficiency, long life, and low cost. Adopting the special flow channel design of the international advanced

This type of mould is assembled from outer cap and an inner anti-theft ring. The outer cap is automatically rotated and pushed out by a hydraulic moto